To say Wesley Hack has embraced battery-powered equipment at his landscaping company would be an understatement.

“Ever since I got on board with this whole electric thing, I’ve become obsessed with it,” says the president of Hack’s Landscaping Creations in Millville, Pa. “I just bought a Tesla car, and we ordered a Cybertruck, but I guess we have to wait until 2022 for that,” he says of the truck that won’t be available until next year.

Hack’s Landscaping Creations employs 22 people, and the business is projected to do about $3 million in revenue this year.

Hack says he decided to go with battery-powered last year, during the pandemic, and didn’t hold back on doing it.

“It wasn’t something that I just bought a few pieces of,” he says. “We have at least two dozen weed whackers and a dozen blowers — backpack and handheld — plus commercial mowers.”

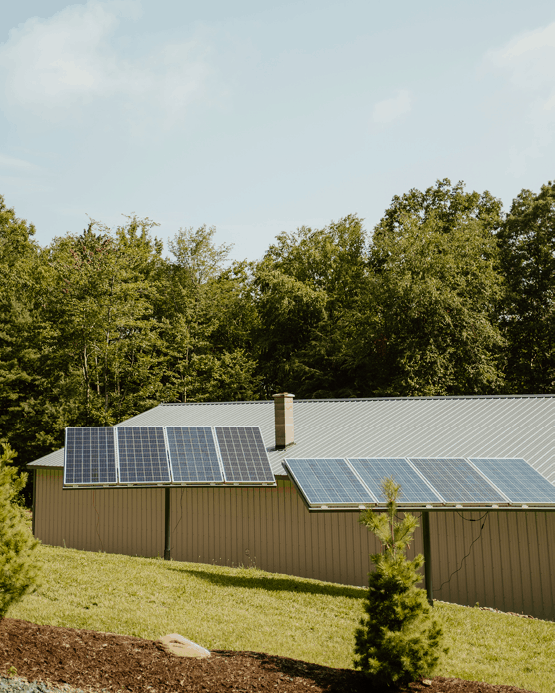

All that battery-powered equipment means a lot of batteries, so Hack came up with a solution to charge everything up.

“We built a solar station,” he says. “I went out a bought a bunch of panels. We built our frame and put them all up. We put in our own inverters and solar controller in. We’re charging all our stuff on it. We’re charging our mowers, our weed eaters, our blowers — all of the batteries for those.”

Hack says that even when the weather isn’t perfect, the batteries can still charge from the solar power, but it may take longer. So, Hack has a “power bank” of batteries on hand that are fully-charged and ready to go.

In Illinois, Sebert Landscape rolled out three completely electric landscaping trailers and crews to start the 2021 season. The company, which landed at no. 42 on this year’s Lawn & Landscape Top 100 List, did $50.5 million in 2020 and has 561 employees.

“They are all battery-powered from the line trimmers, to hedge trimmers to lawn mowers they use. There’s no fuel other than for the truck itself,” says Amy Bateman, branch manager of the Bartlett, Illinois, office, where 98 employees work.

Sebert has been marketing the electric trailers separately this season in specific locations, Bateman says.

“We’ve selected areas where we feel fit the need for the machines to be used and keeping them within a central location…where they are on a lot of more sustainable properties, and where people are more concerned about emissions and the environmental impact,”she says.

Bateman says her crews started with three battery-powered mowers out in the field and they promptly grew that to six. Now, they are up to nine mowers between the three trailers.

“We’ll only continue to add from here,” she says. “I suspect that, at least here in our office where we’re piloting this, we will add the same amount next year and continue on.”

Up north in Wisconsin, Fred Westerfeldt, owner of FRW Landscape Maintenance, has been using the same brand of handheld tools for years but was recently looking to try something different.

Westerfeldt says he came across a trailer filled with battery-powered equipment at a tradeshow. Shortly after seeing it in action, he decided to get on board and try it out for himself.

“I bought a hedge trimmer, a small chainsaw and I bought a blower that were all battery-powered,” Westerfeldt says. “Two of them can run off of the same battery, so I just bought one charger and two batteries for it.”

Charge is crucial.

Soon, the solar station won’t be the only place for Hack’s crews to recharge. “Right now, we’re getting our first trailer set up and it’s going to have batteries storage already in it,” he says. “There’ll be two panels on the roof, so we’ll be able to charge on the go as opposed to just the guys coming home at the end of the day and plugging in.”

Hack says for smaller handheld equipment, it only takes about 45 minutes to get a battery back to full charge. He adds that the mowers obviously take a lot longer.

The batteries Hack utilizes come with a five-year warranty. “We haven’t had any problems with them yet since we just started this last year,” he says. Hack notes that when it’s time to dispose of the batteries, he plans to recycle them.

Bateman says Sebert’s crews are also charging on the truck.

“The trailers themselves are outfitted with their own charging stations,” she says. “So, the batteries get charged within that station and the mowers get plugged into the trailer at night. And that trailer gets plugged into our exterior charging within our maintenance yard.”

She says this setup has seriously cut down on the time it takes crews to get ready at the start of the day.

“In the morning, they are unplugging all that stuff, checking to make sure things are charged properly and if they have to swap some batteries they do,” she says.

Proportionate power.

Bateman says she expected some pushback when they first introduced the electric trailers.

“Whenever new equipment or change comes along, it’s very hard within the culture to get them to adapt. Change can be very, very difficult,” she says. “We’ve surprisingly not had any issues with it.

“We expected a lot of resistance, because usually when you hear ‘battery-powered’ they think less power,” Bateman adds. “But we did a training day with the individuals who’d be running these machines, and not a single one of them complained or said there wasn’t enough power. They were very surprised about how much power they did have. We did not have any complaints.”

Before debuting the electric mowers, Bateman says she and others from Sebert’s toured the manufacturing facility where the mowers were made, and the supplier spent time educating them on the mowers. Then, the suppliers made the trip to Illinois to assist at the training event.

“We went through different videos on how the machines work…then we did some hands-on stuff to show them how to change blades and stuff. We had the mowers raised up and showed walked them through how to disconnect things, how to charge them and all that,” Bateman says. “Then, we took them out to a property we maintain and had them all run the mowers to get the feel of it…We set up cones and different things for them to weave in and out of.”

During the day of training, Bateman says everyone got a chance to test out the mowers – not just the crews who’d be operating them out in the field.

“We actually pulled a couple women from our human resources department and got them out and on the machines. These are girls who’ve never been on lawn equipment before, but they took off and were really impressed with how they could move them around,” Bateman says.

Matt Leakakos, account manager with Sebert’s Bartlett office, says crews haven’t run into many problems with losing power mid-day.

“We are getting about six hours on a full charge,” he says. “And that’s about a full day, with lunch and travel worked in.”

Hack says he’s also noticed no issues with the equipment not generating as much power as gas-powered machines.

“I think the performance is even better,” he says. “With the blowers, there’s more power. And it’s instant…the technology is just amazing and it’s getting even better.”

However, Hack admits that if a battery-powered mower dies while out in the field — it’s (temporarily) game over.

“With the riding mowers, you can’t just pull the battery out and change it,” he says. “They’re built into the mower, so you might only be able to do half as many (lawns) as you’d be able to do before. You can’t complete all the lawns with just one or two mowers unless you’re able to charge while you’re out.”

“We are getting about six hours on a full charge. And that’s about a full day, with lunch and travel worked in.” Matt Leakakos, account manager with Sebert Landscape’s Bartlett, Ill., branch

Hack says the terrain being maintained with the mowers also factors into their performance.

“With a mower, you can probably get three quarters of the day. If you’re going up hills all day, you’ll get even less,” he says. “But say you’re mowing a field or something and really hammering it — it works like anything with electric, the harder you use it you won’t get as much out of it.”

Westerfeldt says he was initially skeptical his new battery-powered equipment would have enough power.

“I wasn’t sure what to expect, because from the people I talked to who use battery-powered, they said they get a full 12 minutes of use out of it,” he says.

But Westerfeldt says he found out quickly that wasn’t the case.

“One of the places I take care of is a mini-golf course and it’s a pretty good-sized place,” he says. “So, it normally takes me two hours to go around the course. Well, I went all the way around and I still had battery left.”

Even so, Westerfeldt says there’s some tasks, like trimming lilac bushes, that still require him to use gas-powered tools.

“For about 80% of things I do, the battery-powered is good enough,” he says. “If I go to new places and you’ve got a lot of overgrown bushes or things, and you’re cutting through a lot and need horsepower, it might take me a few hours, so I wouldn’t have enough batteries. And batteries are expensive.”

Turning down the volume.

Bateman says that while the power is comparable, another benefit of battery-powered equipment is it’s much quieter.

“You don’t hear that noise and that engine rumble,” she says.

Leakakos adds customers have been appreciative of the lower volume.

“We do an HOA with those mowers and I think one of the residents saw them mowing and commented about how quiet they are,” he says. “It is a big difference. Obviously, we’ve gotten complaints before on those sites about the noise early in the morning, but we really haven’t had those yet this year.”

Despite the reduced noise, Bateman says the crews aren’t permitted to start any earlier on the HOAs. “It doesn’t matter since there’s that mindset of, ‘well, we see someone so they’re making noise,’” she says.

“(Commercial clients) don’t like to have the noise from the gasoline engine, so the battery equipment works really well.” Fred Westerfeldt, owner of FRW Landscape Maintenance

Westerfeldt says making the switch has also allowed him to free up his schedule some. Now he can work on some of his commercial clients’ properties at all times of day and not worry about affecting their guests.

“I live in a small community, but it’s a big tourist town,” Westerfeldt says. “I got the battery equipment, especially for some of these commercial places, because I can’t always get in there and get the work done before they open up for the morning. They don’t like to have the noise from the gasoline engine, so the battery equipment works really well. It doesn’t interrupt them as much, and that helps me out quite a bit.”

The lack of noise is also beneficial for crews, too. Bateman says she knows hers have enjoyed the quieter work.

“The same goes for the field staff,” she says. “The guys have their earplugs in and are used to that droning of the engine all day long, but as of now, they can hear everything that’s going on. It’s definitely a nice break for them.”

Plenty of other perks.

But Leakakos says the benefits of the equipment go beyond noise level: He’s also noticed less maintenance needs on his equipment this season.

“The other thing we noticed was that without having to use oil or anything like that, the maintenance time has drastically decreased,” he says. “With a propane- or gas-powered machine, it’s a couple hours a week doing maintenance. With these, we just have to sharpen the blades and change the blades — that’s it.”

Hack says lowered maintenance costs have also been a benefit for his company. He expects to start seeing a return on his investment soon.

“I think you can get a return in about three years, but maybe even quicker,” he says.

Leakakos says time management is also better this year, as crews are out the door fast and don’t have to make as many stops.

“They don’t have to stop and get fuel; they’re just unplugging something and getting started with their day. They don’t have to deal with any other equipment issues,” he says.

Westerfeldt adds that last year, he saw some minor fuel savings after switching over to battery-powered equipment.

“When I sat down with my accountant this spring to do my taxes, I keep a log of gasoline usage for off-road use and I was down over five gallons,” he says. “It might not sound like a heck of a lot, but each fill up on the tank is 12 ounces or so. It amounted to a fair amount.”

Green machines

From lawn mowers to handheld tools, electric equipment continues to advance.

Graze Mowing – Autonomous Commercial Lawn mower

The pitch: A fully autonomous and electric commercial lawn mower that is controlled via GPS, Lidar and smart sensors.

- Machine learning, coupled with computer vision and a system of sensors, allows the mower to map jobsites, plan and execute mowing paths, and avoid obstacles and dangerous inclines, all while collecting and applying data.

For more info: Grazemowing.com

Greenworks Commercial 82SP25M 25-inch Self-Propelled Lawn Mower

The pitch: This self-propelled Mower delivers optimal cutting performance with two cutting blades and a 25-inch width cutting path.

- Dual Battery capability provides AutoSwitch technology from first battery to second for uninterrupted runtime.

- Deliver fine mulch or bag clippings in a 15.5 gallon grass collector.

For more info: Greenworkscommercial.com

M12 FUEL HATCHET Pruning Saw

The pitch: By harnessing the portable productivity, performance and run-time that they can deliver through M12 Fuel technology, Milwaukee introduces the M12 Fuel Hatchet 6-inch Pruning Saw.

- As with all M12 Fuel products, the Hatchet features three Milwaukee-exclusive innovations — the Powerstate Brushless Motor, RedLithium Battery Pack and RedLink PLUS Intelligence Hardware and Software.

- The M12 Fuel Hatchet chain leverages a full-house design with a cutter on every drive link to deliver cleaner cuts and less vibration.

- The M12 Fuel Hatchet 6-inch Pruning Saw is a part of the M12 Cordless System focused on delivering durability and power in the tightest spaces.

For more info: Milwaukeetool.com

Mean Green VANQUISH Electric Stand-On Mower

The pitch: A commercial grade electric stand-on ZTR with all-day power.

- It delivers professional results for up to seven hours of continuous use and recharges overnight.

- It’s available with choice of 52-inch or 60-inch cut, and either side or rear discharge.

- With patented ZTR technologies and ground speeds of up to 11.5 mph, the VANQUISH can handle up to 15 acres on a single charge.

For more info: MeanGreenMowers.com

Oregon 16 in. 40-Volt MAX Electric Cordless Chainsaw

The pitch: The self-sharpening, cordless chainsaw cuts trees and limbs quickly and easily.

- It includes a 16-inch guide bar and PowerSharp chain, which minimizes downtime by allowing you to sharpen your saw right on the chain.

- The chain stays oiled using the built-in Lubri-Tec oiling system, which reduces chain friction and increases the saw’s run time.

- The chainsaw features overload protection, as the motor shuts off automatically if the chainsaw is pushed too hard.

For more info: Oregonproducts.com

Toro 60V MAX Heavy-Duty Battery-Powered Lawn Mower

The pitch: The new Toro 60V Max 21-inch heavy-duty battery powered lawn mower is engineered for contractor-grade performance with zero engine exhaust emissions. Quiet, durable and easy to use, this mower gives you the quality of cut your customers demand.

- The engine exhaust is emissions-free and the machine is powered by the 60V Max Flex-Force Power System.

- The mower features improved mulching and bagging performance with the Recycler Cutting System.

- The mower is also maintenance-free with no air filters or oil changes to worry about.

For more info: Toro.com

Explore the August 2021 Issue

Check out more from this issue and find your next story to read.